Set racking basic correction VGK

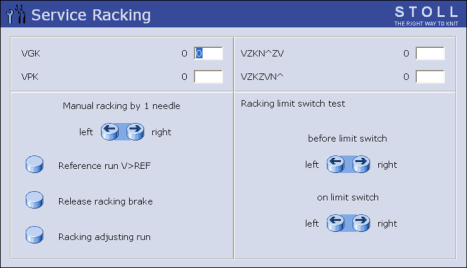

The position of the rear needle bed relative to the front needle bed is set with the VGK value (factory setting).

If part of the racking device is replaced, e.g. the racking motor or the racking belt, the VGK value has to be set anew. During installation, make sure that the front and rear needle beds are opposite each other.

The VGK value always remains saved, even if the operating system is imported again.

|

Key |

Function |

|---|---|

|

|

Call up the menu |

|

|

Call up the window |

|

|

Confirm input |

|

|

Call up |

Adjusting VGK:

- Cast-off the stitches on both needle beds.

- 1

- Call up .

- 2

- Call up the menu.

- 3

- Call up the window.

- 4

- Enter and confirm the value in the line .

- 5

- Tap the key. A message appears, answer this with .

- The needle bed moves to the left and right. The racking will be synchronized.

- 6

- Tap the key. A message appears, answer this with .

- The needle bed moves to the left and right. The racking is carrying out a reference run.

- 7

- Program an empty row with half racking and fix the knitting specification.

- 8

- Push up several opposing needles at various positions of the needle bed (left, center, right) on both needle beds until the needle hooks touch each other.

- 9

- Check whether the needle hooks of the front and rear needle bed are exactly in a line.

- 10

- If this is not the case: Push back needles somewhat so that they do not touch each other anymore. In the line, enter the value using the slider.

|

-1…-150 |

Correction to the left (1 step = 0.01 mm) |

|

+1…+150 |

Correction to the right (1 step = 0.01 mm) |

- 11

- Confirm input.

- The needle bed moves lightly to the left or right.

- 12

- Check whether the needle hooks of the front and rear needle bed are exactly in a line.

- 13

- If this is not the case, repeat steps 10 to 12 until the needle hooks of the front and rear needle beds are exactly positioned in one line.

- 14

- The VGK value is automatically saved in the data specific to the machine (dongle data).

- 15

- Adjust VPK value.

(To be able to determine the VGK value you had to set the VPK value to (in step 4). After having determined the VGK value you must set the VPK value again.)

- The setting process is complete.

If you want, you can save VGK value additionally:

on a USB memory stick

on a network drive (button "Copy Dongle")

Wrong selection - individual needles miss-knit

If a wrong selection occurs, then the synchronisation "Impulse sensor – control – selection system" is not optimal anymore. This has been caused by the big difference between the old and new VGK value.

The "Needle selection displacement" test must be carried out for re-establishing the synchronisation.