Economic production and the influencing factors

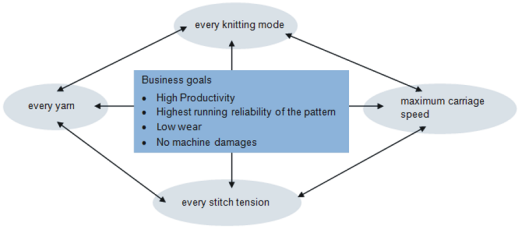

The requirements for a knitting machine can be divided into two main groups: the machine related goals and the business goals.

The knitting machine is to work with maximum speed with every knitting mode, every stitch tension, regardless of the yarn. Simultaneously a high productivity is expected from the knitting machine and the pattern shall be knitted faultless.

The simultaneous achievement of all goals is seldom possible, as there is a conflict between some goals. A conflict because they cannot be accomplished all simultaneously. Between the individual goals there are rather interactions, which can have negative effects on the accomplishment of other goals. In other words, there are goals that cannot be achieved together or that exclude each other.

Example:

One conflict exists between the yarn thickness, the stitch tension and the carriage speed. If the intention is to work at the upper limit, the maximum with all of the three goals, this will lead to a reduced running reliability of the pattern, an increased wear and in some cases even to machine damages.

The influencing factors

|

Running reliability |

|

|

Wear and machine damages |

The unsuitable combination of the influencing factors may lead to increased wear and to the damage of machine parts. |

|

Conclusion |

Therefore the influencing factors have to be adjusted. It's not possible to achieve any carriage speed and stitch tension with every yarn and knitting pattern.

|

Defective machine parts caused by disregarding our guidelines, are excluded from warranty.

Defective machine parts caused by disregarding our guidelines, are excluded from warranty.