Assembling the carriage (ADF)

Extract from the operating instructions

Section

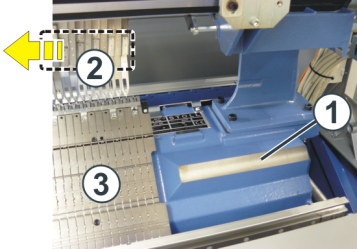

If the front carriage part is returned to the machine, it needs to be pushed from outside on to the support surface (1). The reason for this: The movable parts in the clamping and cutting bed will be pushed by the carriage part (more exactly: by the cam box curves) into their correct position.

Please observe the following procedure:

|

|

Procedure |

|---|---|

|

Front Needle Bed |

|

|

Rear Needle Bed |

|

What is to be considered with the weave-in devices?

- Move the yarn carriers (2) from the clamping and cutting area into the needle bed.

- If you cannot open the lateral safety door completely because of space reasons, we recommend you to dismantle the clamping and cutting bed (3) to prevent the weave-in device from getting damaged.

- 1

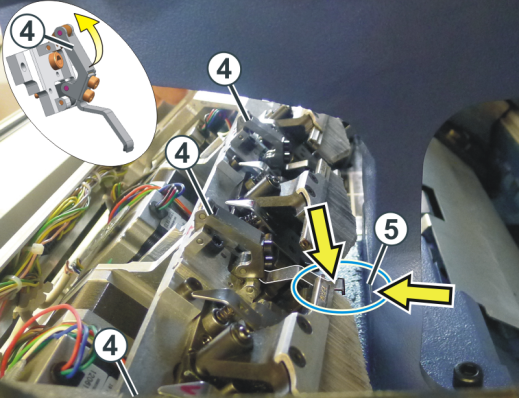

- On the removed carriage part, move manually all the weave-in devices (4) into their upper position (out of operation).

- 2

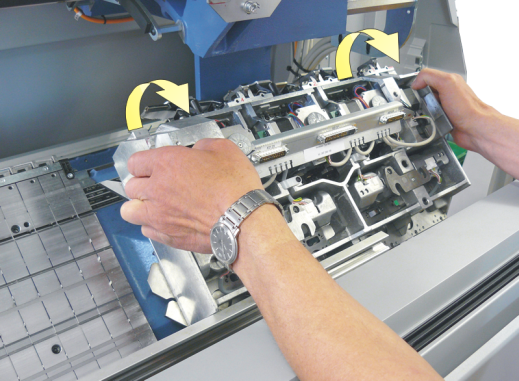

- Push the carriage part from outside onto the support surface (1).

To prevent the weave-in devices from colliding with the support (5) lift the carriage part somewhat and push it inward.

- 3

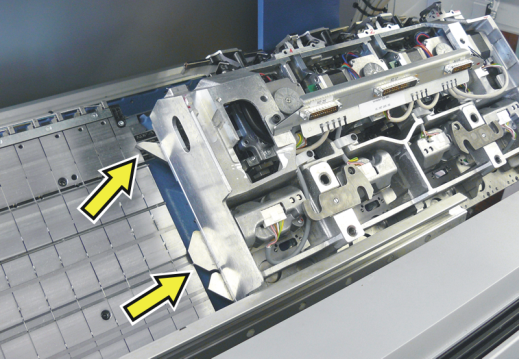

- If the outer cams are positioned above the clamping and cutting bed, position the carriage part on the support surface.

- 4

- Push the carriage part inward and assemble with the carriage assembly.