Lubrication

With this menu you confirm the corresponding lubrication process:

|

Винт на Чупката | |

|

|

Display of the time (by days) until the next lubrication process. |

|

|

Click this button only if the greasing process actually was performed. In case of insufficient grease, there is the risk of damaging the racking spindle. An irreversible damage of the racking spindle is possible!

|

|

Винт на Чупката | |

|

|

Display of the time (by days) until the next lubrication process. |

|

|

Click this button only if the greasing process actually was performed. In case of insufficient grease, there is the risk of damaging the racking spindle. An irreversible damage of the racking spindle is possible!

|

|

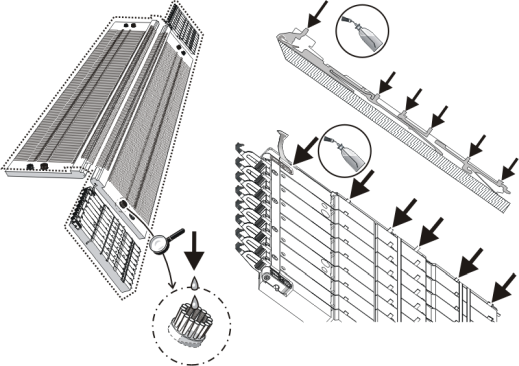

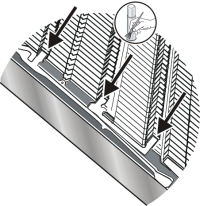

Иглено легло | |

|

|

Displays the quantity of the system run-throughs until the next oiling of the needle bed. |

|

|

Tap on this button only if the oiling process actually was performed.

|

|

|

After every tenth note appears a pictograph.

|

|

|

Click this button only if the greasing process actually was performed.

|

|

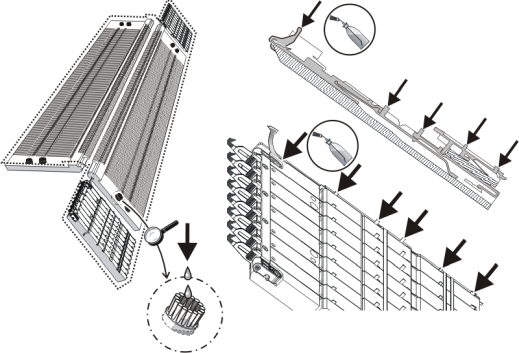

Иглено легло | |

|

|

Displays the quantity of the system run-throughs until the next oiling of the needle bed. |

|

|

Tap on this button only if the oiling process actually was performed.

|

|

|

Click this button only if the greasing process actually was performed.

|

|

Иглено легло | |

|

|

Displays the quantity of the system run-throughs until the next oiling of the needle bed. |

|

|

Tap on this button only if the oiling process actually was performed.

|

|

|

Click this button only if the greasing process actually was performed.

|

|

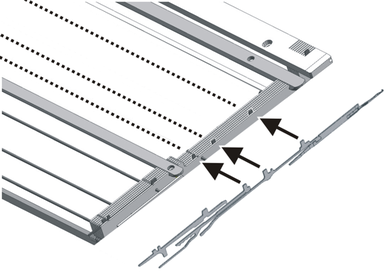

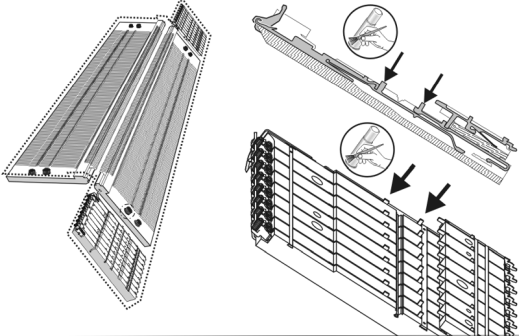

Линеен Водач на Шейната | |

|

|

Display of the time (by hours) until the next lubrication process.

|

|

|

Display of the distance (in kilometers) until the next last lubrication process.

|

|

|

Display of the previous operating time of the carriage (operating hours counter) |

|

|

Display of the traveled distance of the carriage (kilometer counter) |

|

|

Click this button only if the greasing process actually was performed. In case of insufficient grease, there is the risk of damaging the linear guiding. An irreversible damage of the linear guiding is possible! |

|

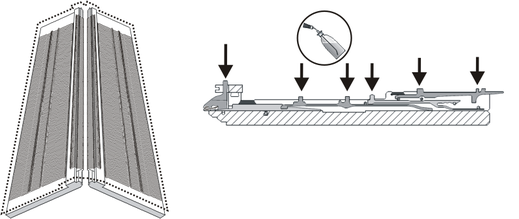

Иглено легло | |

|

|

Displays the quantity of the system run-throughs until the next oiling of the needle bed. |

|

For central lubrication Type1

| |

|

|

Централното смазване, еднократно смазва цялото иглено легло. |

|

|

Tap here to deaerate the oil line of central lubrication. |

If the maximum value for the run time or the distance is reached, the machine stops. The

If the maximum value for the run time or the distance is reached, the machine stops. The