CMS Machines

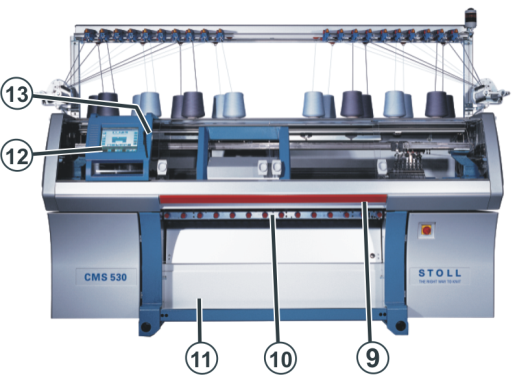

Operating and Signal Elements

|

| Designation | Explanation |

|---|---|---|

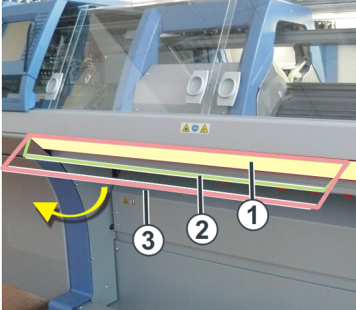

1 | Yarn control device | Monitors the thread. |

2 | Bobbin board | The bobbins are placed on it. |

3 | Carriages | It moves over the needle beds and controls the work positions of the yarn carriers and of the needles in the needle bed. |

4 | Signal light | It displays the operating state of the knitting machine |

5 | Safety door (left, right) | The reversing position of the carriage is secured by the safety door. |

6 | Covers | The entire traversing path of the carriage is secured with covers. You have to forbid everyone from reaching out into the running machine. |

7 | Control |

|

8 | Main switch | Switching on and off of the machine. |

|

| Designation | Explanation |

|---|---|---|

9 | Engaging rod | It activates and stops the carriage run. |

10 | Fabric take-down | Main take-down: Auxiliary take-down: Comb take-down: |

11 | Fabric collection chamber | The fabric take-down guides the finished fabric into the fabric collection chamber. There the fabric is protected from soiling. |

12 | Touch screen | The touch screen enables communication with the machine control |

13 | USB port | Connection for a removable drive, containing knitting programs, operating systems and machine data. |

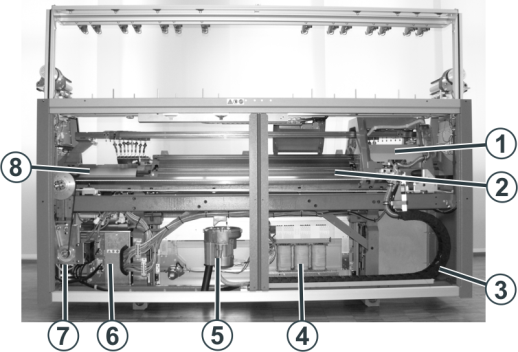

Rear of the machine

|

| Designation | Explanation |

|---|---|---|

1 | Carriages | It moves over the needle beds. It controls the work positions of each yarn carrier and each and every needle in the needle bed. |

2 | Rear needle bed | Every machine has a front and a rear needle bed. There are grooves in the needle bed which are run by needles. |

3 | Trailing cable (energy chain) | The cables for the carriage that travels hence and forth are fed along with in the energy chain. |

4 | Transformer (Fuses) | The knitting machine can be operated with various mains voltages. |

5 | Fluff absorption | The fluff absorption removes the yarn fluff from the upper area of the needle beds. |

6 | Control | It controls the knitting process. It saves the data of the knitting program. It controls the needle selection and the motors in the carriage. |

Control (right-hand side of the machine) | It controls the carriage run and the racking of the needle bed. | |

7 | Main drive | The carriage is driven by the drive motor via a toothed belt. |

8 | Racking device | Racks the rear needle bed laterally. |

Engaging the machine with the engaging rod

|

Positions of engaging rod | |

|---|---|

1 | Carriage stopped |

2 | reduced speed |

3 | normal speed |

Signal light

The signal light (1) displays the operating status (green, yellow) of the knitting machine.

|

Color | State |

|---|---|

green | Knitting machine produces at 100% |

green (flashes) | Knitting machine is stopped with an engaging rod |

green, yellow (flashes) | Knitting machine produces at less than 100% due to manual interventions.

|

yellow | The knitting machine is not producing, as an error has occurred during knitting. |

green, yellow | Both lamps light up during the shutdown process. |

off | Main switch is off. |

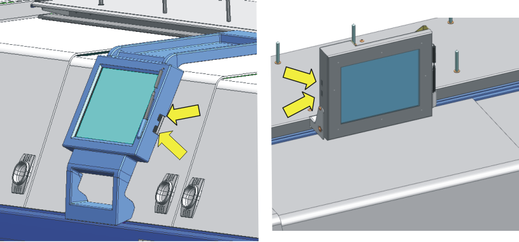

USB Memory Stick

|

All CMS machine types | CMS 502 HP / CMS 502 HP+ |

|---|---|

| |

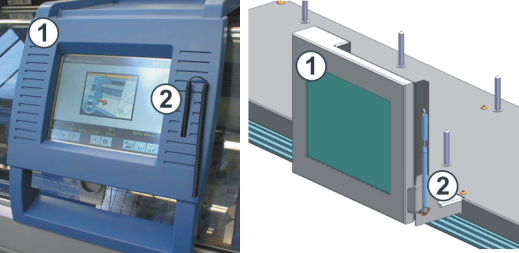

User Interface

|

| CMS 502 HP / CMS 502 HP+ | |

|---|---|---|

| ||

| ||

1 | The input unit enables communication with the machine control | |

2 | Touch pen. | |

Functions at the touch screen (user interface):

- Display of operating data

- Changing machine settings and pattern data

- Input of commands

- Calling up help information