Main Take-down

Types of Main Take-down

|

Compact class |

CMS 502 |

Top class |

|---|---|---|

|

|

|

|

|

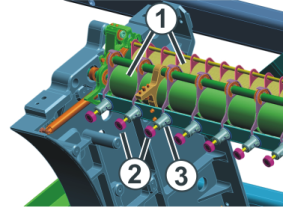

No. |

Elements |

|---|---|

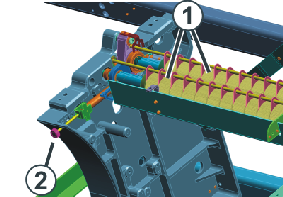

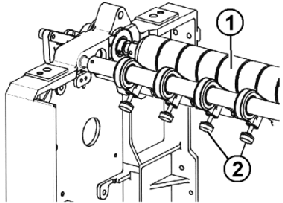

|

1 |

Take-down rollers |

|

2 |

Knurled screws |

|

3 |

Scale |

- A motor drives the take-down rollers (1).

These provide the take-down tension and guide the finished fabric into the fabric collection chamber. - The contact pressure can individually be adjusted with knurled screws (2).

- The scale (3) simplifies the adjustment.

Take-down tension

The take-down tension consists of:

- Pretension at the carriage reversing point (WMI)

- Take-down tension during knitting (WM)

You can set both take down values independently of each other.

The optimum value for the take-down tension depends on:

- Working width

- Yarn

- Pattern

Premature wear of the take-down rollers

The roller rubber of the take-down roller (1) is prematurely worn by:

- Fabric take-down values too high (roller spins)

- Contact pressure too high

- abrasive, sanding yarns

- yarn finishes such as greases or oils

- UV radiation

- Cleaning agents harmful to rubber.

Use cleaning petrol!