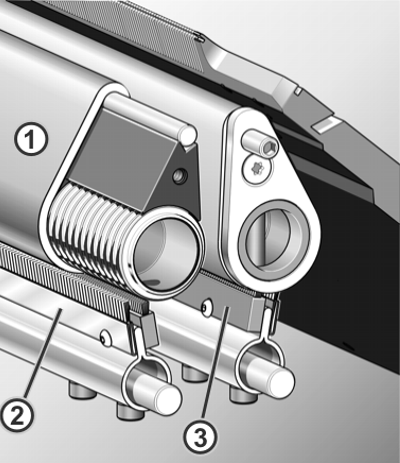

Belt Take-Down

|

1 |

Belts |

|

2 |

Antistatic brush |

|

3 |

Linear stripping brush |

How the belt take-down works

The belt take-down grasps the fabric directly under the needle bed.

A motor drives the drive shafts. The belts (1) are driven by the drive shaft and guided by the deflection rod. The finished fabric is guided into the fabric collection chamber by the belts.

The winding protection device with antistatic brushes (2) and linear stripping brushes (3) avoid the winding of the fabric and the threads around the take-down belts. If winding is detected nevertheless, the machine stops.

Functional states

- Rotate: Forward rotation with controlled speed by the motor

- Stop: After a short delay the forward movement is stopped.

- Close: Short, fast forward rotation, then rotate

- Open: Short, fast backward rotation

Premature wear of the take-down belts

The belt will be worn prematurely by:

- too high belt speed

- yarns that are harmful to rubber, e.g. abrasive, sanding yarns or yarn finishes such as greases or oils

- sharp tools that are used for example for pressing-down the stitches or the fabric

- UV radiation

- Cleaning agents harmful to rubber, e.g. ether or fuels. Recommendation: Use cleaning petrol for cleaning