Correction of Presser Feet (ESCI) on W Machines

For some patterns, the problem may arise that the weft yarn presser foot does not catch the thread properly.

|

Possible causes

| - Quality of the weft yarn (friction coefficient, elasticity, twisting, moisture, hairiness, tensile strength)

- Yarn gauge of the weft yarn, yarn count / twisted yarn

- Yarn tension, yarn feeding

- Weft yarn is not in center of the needle bed gap

- Long float of the weft yarn.

The float arises when the end position of the weft yarn in the previous row and the starting position of the following row are far apart.

|

Task of the weave-in device

| - Shift-in position

The presser foot has to catch and guide the weft yarn in order to get safely enclosed. - Shift-off position

The presser foot secures the weft yarn until it is enclosed at the last needle.

|

Solution

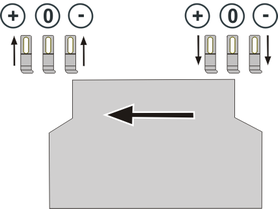

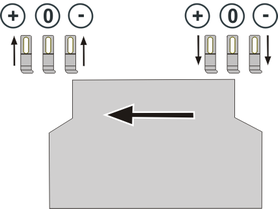

| You can adjust the shift positions of the weft yarn presser foot to the corresponding knitting situation.

0 = shift position (default)

+ = later shift position (1…120 steps)

– = former shift position (-1…-120 steps)

↓ = shift-in position

↑ = shift-off position

|

Programming

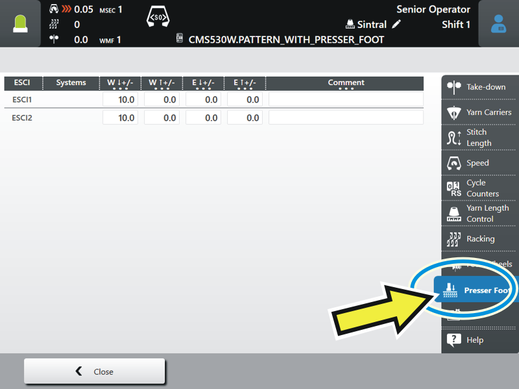

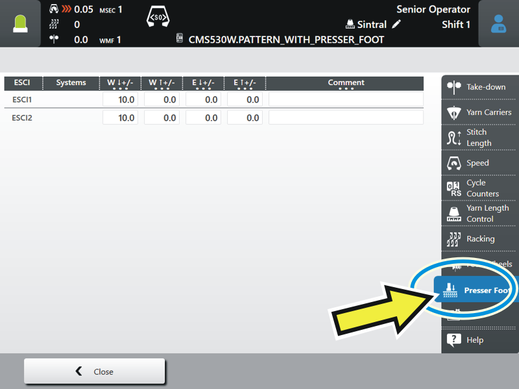

| - On the M1plus:

Specify the indices (ESCI1, ESCI2…) for the corrections of the presser feet on the M1plus (Presser Foot control column  ). ). - On the knitting machine

You can specify the correction values in the Presser Foot menu of the Setup2 Editor.

The optimal adjustment depends on the yarn and the pattern. This adjustment is the easiest to undertake while the machine is knitting.

|

Setup2 – "Presser Foot" tab

).

).