Intarsia Yarn Carriers with CMS Machines and their way of working

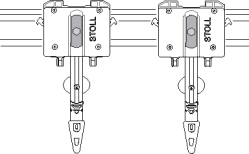

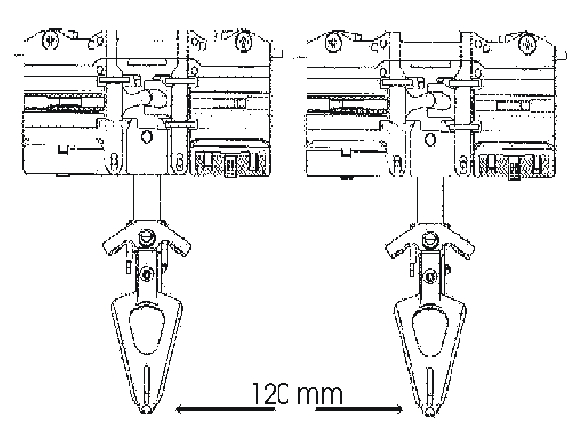

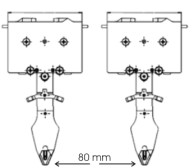

Yarn carrier types:

|

Normal yarn carrier type 1 | Normal yarn carrier type 2 | ||

|

| ||

| |||

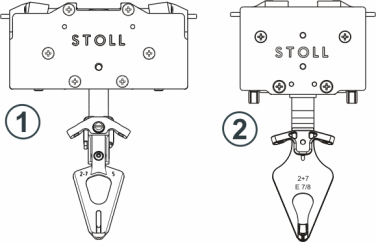

Intarsia yarn carrier type 1 | Intarsia yarn carrier Type 2 | ||

|

| ||

| |||

1 | Intarsia yarn carrier type1 | Use with CMS machines CMS 530 C and CMS 830 C with the old yarn carrier drive | |

2 | Intarsia yarn carrier type2 | Use with CMS machines starting with OKC 3.0 control with new yarn carrier drive | |

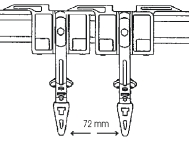

Combination of normal yarn carriers type 1 and intarsia yarn carriers type 2:

A normal yarn carrier type1 and an intarsia yarn carrier cannot work on the same yarn carrier rail.

|

Yarn carrier types | Combination of the yarn carriers on one rail |

|---|---|

Normal yarn carrier type 1 Intarsia yarn carrier type 2 |

|

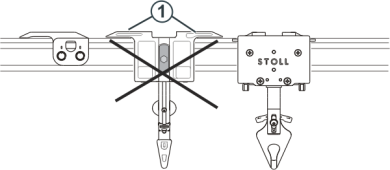

The disengaging arms (1 ) at the normal yarn carrier type 1 collide with the intarsia yarn carrier or the yarn carrier limiter. |

Tip:

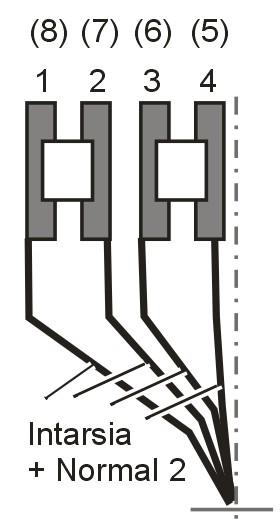

Equip the yarn carrier rails from inward to outward.

Benefit:

With the allocation from inward to outward no track must be kept empty when using intarsia and normal yarn carriers.

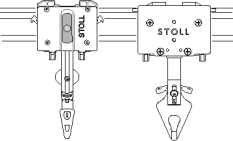

Combination of normal yarn carrier type 2 and intarsia yarn carrier type 2

|

Yarn carrier types | Combination of the yarn carriers on one rail |

|---|---|

Normal yarn carrier type 2 Intarsia yarn carrier type 2 |

|

Normal yarn carrier type 2 Normal yarn carrier type 2 |

|

| |

Advantage |

|

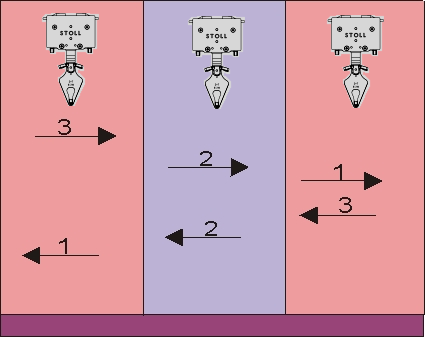

Sequence of the knitting technique with intarsia:

Consecutively, uniformly knitting intarsia yarn carriers:

The result is a nice, uniform binding at the color field edge = high quality.

With a high quantity of colors per knitting row this sequence leads to a high production time.

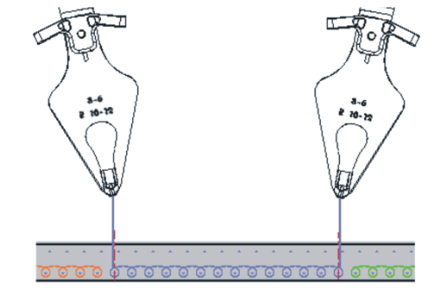

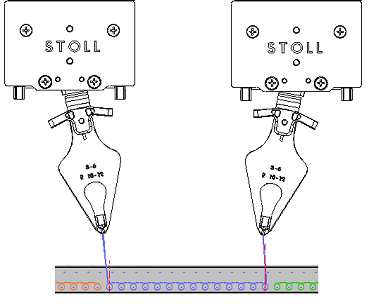

Way of working of an intarsia yarn carrier type 2 with CMS Machines:

- An intarsia yarn carrier is set upright from its swiveled position before knitting.

- Knitting of the yarn carrier in its color field.

- The brake is actuated and the yarn carrier is stopped at the end of the color field.

- Swiveling the yarn carrier in its color field i.e. opposite to the carriage direction.

The yarn carriers stopped in the fabric are swiveled.

The yarn carriers stopped at the fabric selvedge are not swiveled.

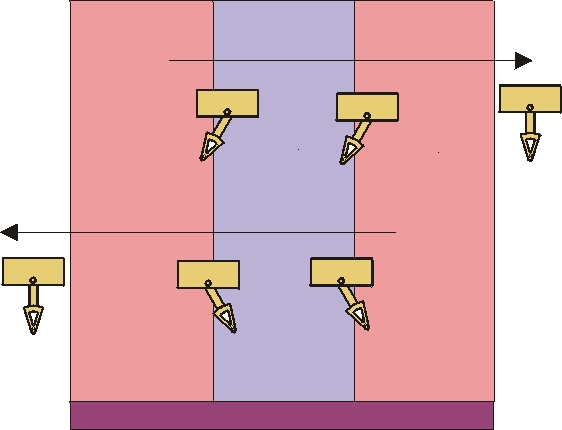

Parking position of a swivelled intarsia yarn carrier:

|

Parking position |

|

|---|---|

Not correct The yarn carrier is in the neighboring field, what can lead to a binding of the thread in the wrong color field. |

|

|

|

Correct parking position |

|

: Yarn carrier positions must be corrected.

: Yarn carrier positions must be corrected.