Lubricate the Knitting Machine

Oiling and greasing:

You have to clean and lubricate the knitting machine regularly in order to maintain the operability of the knitting machine.

When a lubricating interval expires, a message appears:

Oiling or greasing

Use only the lubricants recommended by STOLL.

See operating instructions

Unsuitable lubricants may damage the machine.

Failure to comply will void the guarantee.

|

| Machine gauge | Designation |

|---|---|---|

| E 3-14 E 2,5.2 - 7.2 | Stolltex T46 |

E 16-18 | Stolltex T32 | |

After every tenth note appears to grease needle bed | Stoll Grease 475 |

|

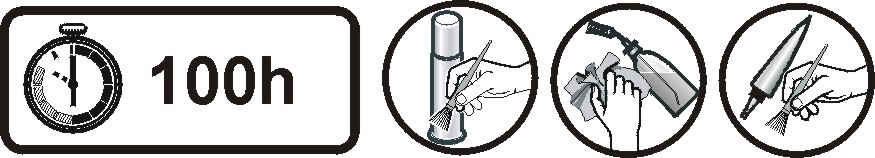

Lubricating intervals | |

|---|---|

6-10 operating hours | Oiling the needle bed without central lubrication. Note: Select a shorter interval if necessary. |

10 operating hours | Oiling the jack bed, the thread clamping and cutting device and the yarn carrier rods. |

100 operating hours |

|

6 months | Greasing the racking device and needle bed supports |

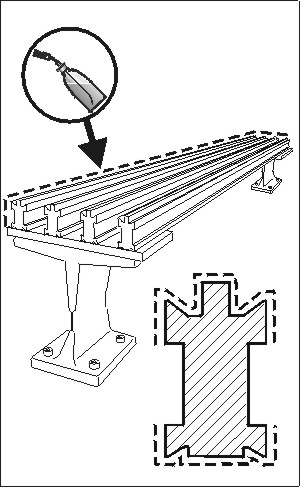

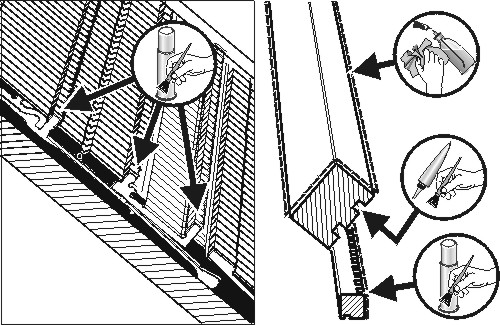

Lubricate with oil:

Lubricate with oil and grease:

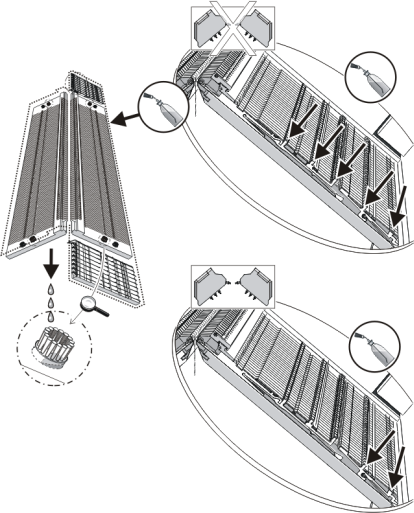

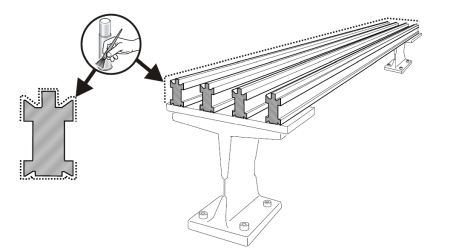

Oiling the needle latch hinges:

- 1

- Use a brush to apply oil to the needle latch hinges.

- 2

- Knit with residual yarn until oil lines no longer appear in the fabric.

Observe the lubrication schedule in the operating instructions.

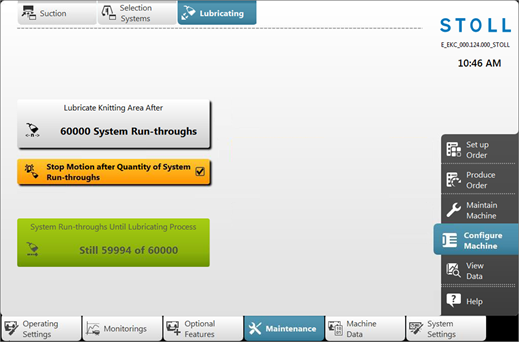

Set the lubrication interval for the needle bed:

The lubrication interval for the needle bed depends on:

- Machine speed

- Ambient temperature

- Number of knitting systems

- You are signed in as Senior Operator

.

. - The knitting program is loaded and the production was started.

- 1

- In the main navigation bar select

Configure Machine.

Configure Machine. - 2

- Tap on

Maintenance in the bottom navigation bar.

Maintenance in the bottom navigation bar. - 3

- Open the

tab.

tab.

- The following menu is displayed.

- 4

- Press the

Lubricate Knitting Area After button.

Lubricate Knitting Area After button. - 5

- Via virtual keyboard, enter the desired value (a maximum of 60 000 run-throughs).

- 6

- Confirm the entry with the

OK button.

OK button. - 7

- Button

Stop Motion after Quantity of System Run-throughs:

Stop Motion after Quantity of System Run-throughs:

- Active

: After reaching the lubrication interval, the machine stops.

: After reaching the lubrication interval, the machine stops. - Inactive

: After reaching the lubrication interval, the machine is not stopped.

: After reaching the lubrication interval, the machine is not stopped.

Note: Under  Przebiegi systemu aż do procesu smarowania is displayed the current state of the lubrication interval.

Przebiegi systemu aż do procesu smarowania is displayed the current state of the lubrication interval.