Deaerate central lubrication[Outdated translation - Switch to English or German]

- 1

- Stop carriage outside needle bed.

- 2

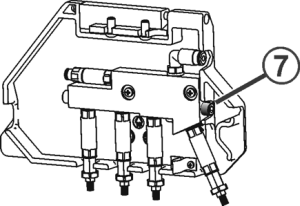

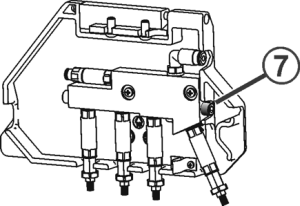

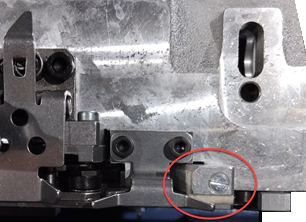

- Loosen vent screw (7) somewhat.

- 3

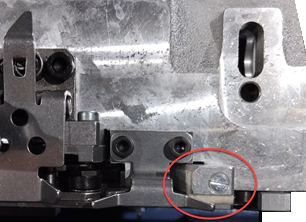

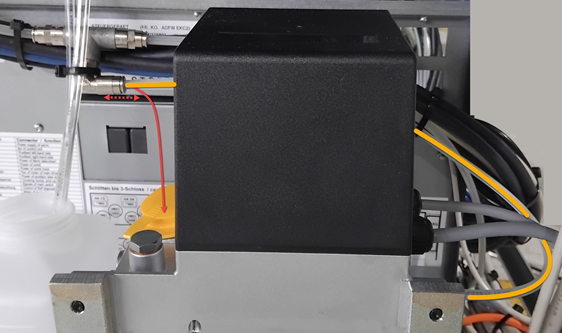

- Swivel central lubrication into mounting position.

Recommendation: Place a cleaning cloth under the central lubrication, as oil will be fed.

- 4

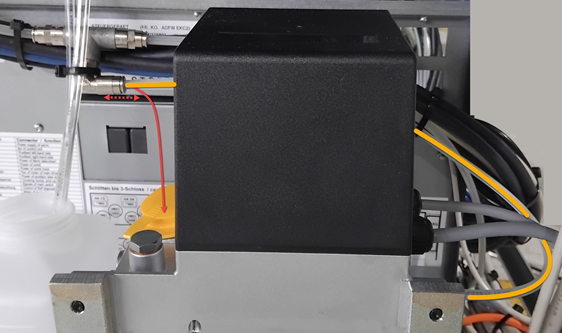

- Activate the Thoát hơi button.

Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi

- The pump feeds oil into the oil line.

- 5

- If oil comes out of the hole of the vent screw, switch off the Thoát hơi button.

- 6

- Tighten vent screw again (9.5 Nm).

- 7

- Repeat the deaeration process on all lubrication units.

- 1

- Stop the carriage on the needle bed.

- 2

- Activate the Thoát hơi button.

Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi

- The pump supplies oil to the lubrication points.

- 3

- Feel the lubrication point for holding-down jacks next to the left needle brush with your finger.

- 4

- If oil leaks from the felt of the lubrication point for holding-down jacks, switch-off the Thoát hơi button.

- 5

- Check for oil leakage at the lubrication point for holding-down jacks of the opposite carriage.

- 6

- Push the carriage from the current location.

- 7

- Check the lubricated points on both of the needle beds and clean-up excess oil.

- Required for initial commissioning, after a long period of downtime or refilling

- Ensure that the lubricant container is free of bubbles.

- Consult the SKF Gear Pump Unit's instructions.

- 1

- Detach the oil line at the first metering device and lead it into the lubricant reservoir.

- 2

- Therefore, press the ring of the metering

device and tear out the line simultaneously.

- 3

- Activate the Thoát hơi button.

Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi

- 4

- Only turn the Thoát hơi button off again when oil flows into the lubricant reservoir without bubbles.

- 5

- Plug the line into the metering device again.

- 6

- Repeat the ventilation process at the subsequent lubrication points.

- 7

- Run the pump until oil can be seen discharging at all lubrication points.

Thoát hơi

Thoát hơi

Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi

Bảo trì Máy ->

Bảo trì Máy ->  Bôi trơn ->

Bôi trơn ->  Thoát hơi

Thoát hơi Thoát hơi

Thoát hơi