Distributing manually a knitting order to several machines

Orders can be scheduled distributed onto several machines. The order is distributed in partial orders specifying a piece number per machine:

- With the same basic data

- With the same auxiliary data (tags)

- With the same earliest and latest production times

- With piece numbers per machine whose sum is equivalent to the total piece number.

A machine is assigned to each partial order (ticket). The parent order groups the data of the single partial orders (tickets), especially the produces piece number.

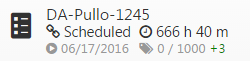

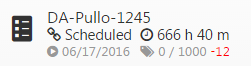

With the end of the distribution, the order changes to the "Scheduled" status or at the choice of the user immediately to the "Released" status. Partial orders change the status as well and are transferred to the machine with the release.

The following grouped information is updated with each change of a partial order:

-

Starting time

Earliest starting time of all tickets -

Expected end time

Latest end time of all tickets -

Number of the produced pieces

Sum of all produced pieces

Distributing a Knitting Order to several Machines:

- 1

- Select from the menu bar.

- 2

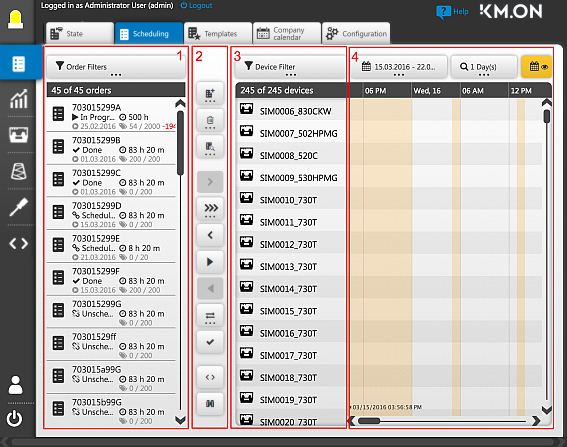

- In the navigation bar select the tab.

- The scheduling view appears.

The orders are displayed in a list on the left (1).

On the right is the machine list (3) with the scheduling timeline (4).

Between both views there is the toolbar of the scheduling (2). - 3

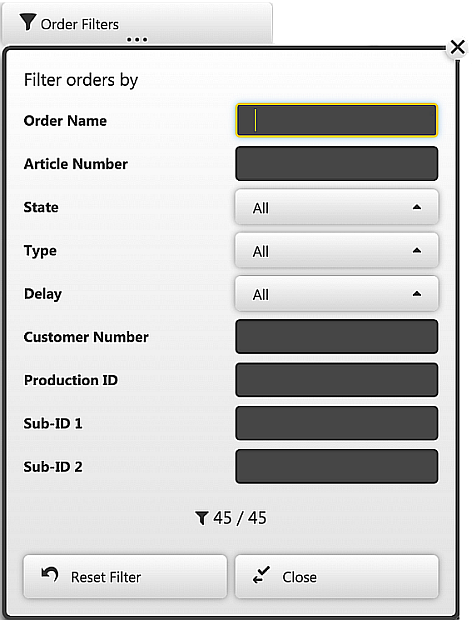

- Select an order.

Use the order filter options (1) for this.

- 4

- Check the work load of the machines that can knit the pattern from a technical point of view.

- 5

- Limit the desired machines via the filter options (3).

- 6

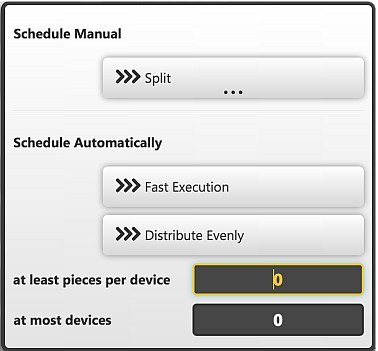

- Select the

Split button in the toolbar.

Split button in the toolbar.

- The selection dialog appears:

- manual distribution of the order by the user onto machines

- automatic distribution of the order by the system (see Distributing a knitting order automatically to several machines)

- 1

- Select the option >>> Split...

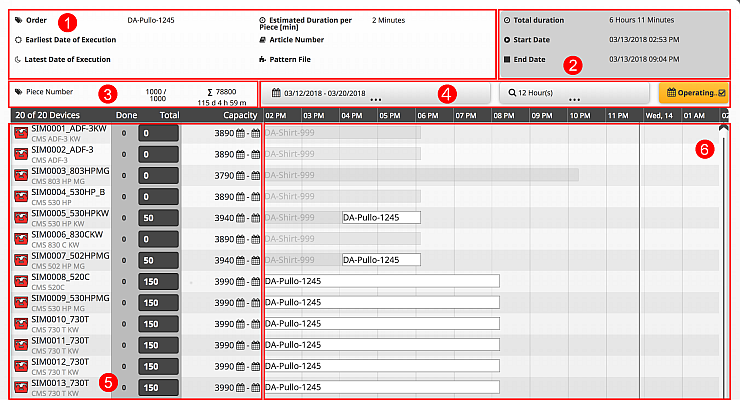

- View for a manual distribution of the order.

The distribution view for the manual distribution of an order has the following structure:

- At the top left is the detailed information regarding the order (1).

- At the top right in the grey box appears the resulting time frame (2). It results from the current distribution.

- At the bottom a timeline view (6) with machines that are suitable for the distribution (5). The selection corresponds to the current filtering in the superordinate scheduling view.

- The timeline view can be set up (4).

- An overview of the scheduled piece number and the total duration is located above the machine list (3).

In the distribution view a piece number can be assigned to each machine, with which you want to process the order (5). A max. production capacity is displayed for each machine. It was calculated based on the currently selected time window of the timeline and the latest possible completion date of the order. Beside each machine entry there is an edit box for recording the piece number. Here, you can make changes as often as needed:

- 1

- Assign a piece number to the desired machines.

- 2

- To be observed:

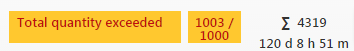

- Total piece number of the order to be read in the overview (3)

In case to many pieces are assigned, it will be visualized.

Surpluses of the quantity are displayed in green positive figures.

If not all of the pieces are covered by the assignment, the number is displayed in negative red figures.

- Production capacities of the selected machines to be read after each machine (5)

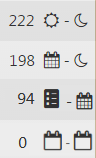

- Sun and Moon indicate that the specified production time period is not limited by the display time period.

- A calendar symbol shows that the production period cannot be fully used, as it is limited by the adjusted display period.

If necessary, expand the display time period to determine the full production capacity. Or limit the time period intentionally, if the you full time period length is not available to you. - An order symbol indicates that the production time period cannot be fully used due to an already positioned order.

- An empty calendar symbol indicates that the defined time period is located outside the specified production time period.

Or the specified production time period is in the past and a timely production is no longer possible.

- 1

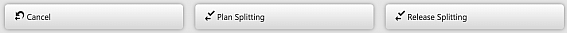

- Verify whether the distribution is satisfactory.

- 2

- You can change the order status from Schedule distribution to Scheduled if the result satisfies you.

- or -

You can change the order status from Release distribution to Released.

- The selected order is distributed to the desired machines in the selected ratio.

Either scheduled or released - Delays will be displayed beside the time period / zoom if the defined completion times of the orders are exceeded.

An unexpected 0 for the production capacity may be due to the time window in the timeline being set up incorrectly regarding the earliest and latest execution time of the order or the selected forecast time period is too small.

Defining the time period for considering the company calendar in the forecast