Preparation of the autoproduction

There are different variants to use the APM mode, which depend on the pattern loading conditions. The simplest case is that you load the complete pattern with the ticket.

How to prepare the autoproduction on OKC:

- You have installed a EVP for PPS and for APM..

- The safety switches are mounted at the rear panel and they are attached.

- 1194

- Close the covers.

- 1195

- Execute a reference run if it is not yet performed.

- 1196

- Position the carriage in the left reversion.

- 1197

- Set the piece counter to 0.

- 1198

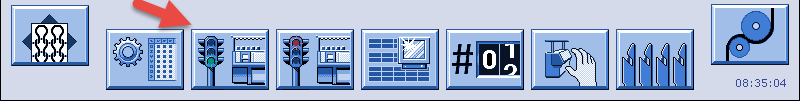

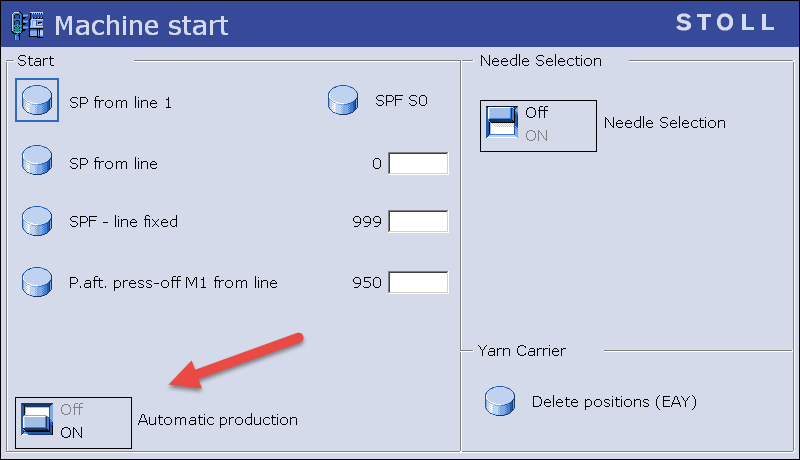

- Set the APM switch in the starting window to ON.

- 1199

- Pull up the engaging rod.

- The engaging rod engages.

- The machine is now prepared for the APM operation.

How to prepare the autoproduction on EKC:

- You have installed a EVP for PPS and for APM..

PPS Connector, APM Extension + - The safety switches are fitted to the rear panel, and the rear panel is attached.

- The Production Management function is activated.

- 1200

- Close the covers.

- 1201

- Perform a reference run, if it has not already been performed.

- 1202

- Position the carriage in the left carriage return.

- 1203

- Set the piece counter to 0.

- 1204

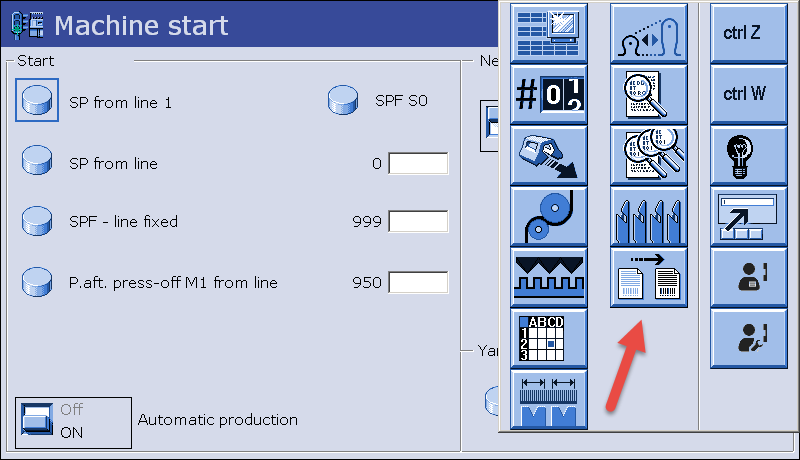

- Activate .

Produce

Order

Produce

Order

Edit Ticket

Edit Ticket

- 1205

- Pull the engaging rod.

- The engaging rod engages.

- The machine is now prepared for APM operation.

- If the reference of the take-down motors and the comb was not yet carried out, the machine switches off on the right side.

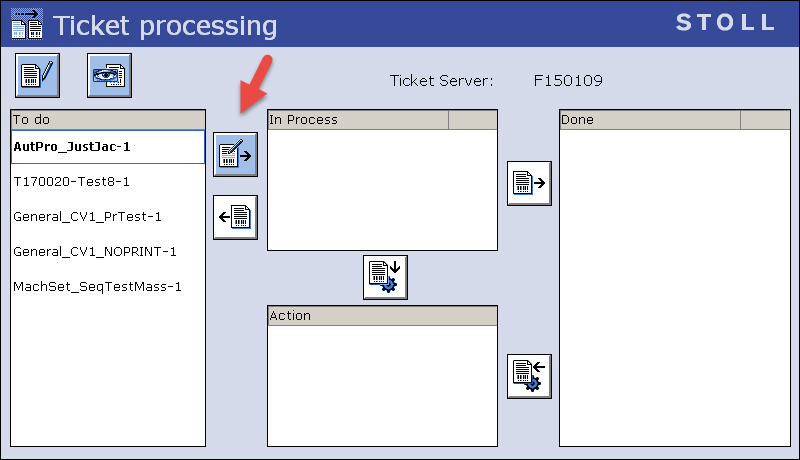

After the reference, the engaging rod must be pulled up again. - If there is already a ticket with the order type autoproduction at the top of the list in the , this ticket will be loaded.

Otherwise the machine waits until such a ticket arrives. - Tickets that are not for production and which can be executed asynchronously (e.g., service ticket) are skipped.

If a General Production, Guided Production, Pattern Setup or Machine Setup ticket exists, the machine waits until an APM ticket is at the top of the list. - Tickets can still be loaded manually.

- Tickets can still be loaded manually.

-

Produce

Order

Produce

Order

Edit Ticket

Edit Ticket

Start

Start - When deferring a ticket, a trigger is needed for automatically loading again a ticket.

This prevents that the ticket will immediately be loaded again.

The trigger can be: - The arrival of a new ticket

- Changing the ticket order

- Removing a ticket

- Switching off and on again the autoproduction

- Disengaging and engaging again the rod

- With a stop motion the engaging rod still falls down.

Eliminate the error and engage again. - When loading the ticket , , is executed by default in contrast to.

You can specify a different behavior in the order by setting the following tags to false or true . - ERASE_ALL

- ERASE_ALL_YARNCARRIERPOS

- ERASE_ALL_SEQYARNCARRIERPOS

- ERASE_ALL_YLC

- In general, the machine tries to load all parts of knitting program.

With the LOAD_PAT_CONTAINER_COMP tag, you can specify the pattern components not to be loaded via the optional attributes SIN, JAC, SET (false).

If a part of the knitting program container (*.zip) is missing, the machine will use the remaining part already loaded. - Refer to Considering different pattern loading conditions if you want to reload Jacquards only or to keep modified Setup data.

Determine the volume of orders on the machine

- With data base queries you can collect information for feeding the machine with tickets.

See How to perform database queries for automation purposes