Intervene Manually I

|

|

Cleaning the touch screen To prevent menus and function keys from being activated when cleaning the touch screen, tap the button. The touch screen will be blocked for 15 seconds. If this period is not enough, tap the button again.

|

|

|

Opens the dialog box to send a message to the Senior Operator or the maintenance staff. |

|

|

The production of the current order will be interrupted. Starting with the next Reversal, the carriage moves back and forth without knitting (empty row). If you deactivate this function, the production will continue automatically. For example:

So that you can see immediately that the production was interrupted, a pause character (II) is displayed.

|

|

|

The speed is reduced.

So that you can see immediately that no optimal production is possible with this setting, the color of the information area changes from green to yellow.

|

|

|

Cancels the current fabric, and starts a new one of the current position (knitting program).

|

|

from line |

You will be asked, at which row the knitting program is to be started. The machine automatically begins with a new fabric.

|

|

|

Delete all yarn carrier positions. Example: The fabric piece is defective and you stop the carriage. In order to remedy the error you push the yarn carriers outward into clamping position and clamp the threads manually. Before restarting the fabric piece you should know the following details: | |

|

If the yarn carrier positions are not deleted | ||

|

|

| |

|

The yarn carrier positions are deleted | ||

|

|

| |

|

|

Opens the dialog box to enter the Sintral line number where picking-up after pressing-off starts from.

|

|

|

|

|

The carriage stroke will be extended by the set option. If you tap on the icon

So that you can see immediately that no optimal production is possible with this setting, the color of the information area changes from green to yellow.

|

|

|

The machine automatically begins with a new fabric if the following conditions are met:

As long as these conditions are not met, cycles (RBEG...REND) will only be knitted once. |

|

|

Switch the needle selection on or off. For example, when a needle is broken and the carriage is therefore blocked. |

|

|

The production of the current order is cancelled. Starting with the next Reversal, the carriage moves back and forth without knitting (empty row). For example if you want to exit the production to:

|

|

|

|

With the function Create Initial State there are carried-out the following steps:

Attention : If you need to carry out a different work procedure for the restart of a fabric, e.g. when working without comb take-down, we recommend not to use the function Create Initial State. |

|

Return the machine to the initial state. With this, the individual aggregates (carriage, yarn carriers, racking,...) are brought to a defined state step by step. When the steps are processed, the initial state is created and the machine is ready to knit. Afterwards you can:

| ||

|

|

The selected line will be repeated continuously until you restart the knitting program. When carrying out cleaning, adjustments and repair work, it is helpful if a certain knitting situation (line) can be set-up immediately and repeated as often as needed. |

|

|

Switch on or off the lighting of the needle beds. If the lighting is switched off, the following icon is displayed on the button. |

|

|

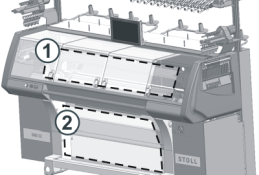

The lighting for the needle bed and the fabric collection chamber can be switched on or off individually.

|

|

|

Switch on or off the lighting of the needle beds 1. If the lighting is switched off, the following icon is displayed on the button. |

|

|

Switch on or off the lighting for the fabric collection chamber 2. If the lighting is switched off, the following icon is displayed on the button. |

|

|

Stopping of the machine when the set condition is fulfilled (conditional stop). |

|

If you tap on the button, you can select one of the following options:

|

|

|

Switch fluff absorption on or off. The needle beds in the knitting area are vacuumed off with the fluff absorption automatically. If you tap on the icon

|

This function is only active if the order consists of one knitting program.

This function is only active if the order consists of one knitting program.

, you can select one of the following options:

, you can select one of the following options: