Minimize Wear[Exported for translation]

All parts of the knitting machine have been carefully manufactured and tested by STOLL. Nevertheless, they are subject to wear.

You can keep the wear to a minimum if you check, clean, and lubricate the machine regularly and use it as intended.

The following table contains an overview of the wearing parts and the possible causes of excessive wear.

|

Wearing part |

Possible causes of increased wear |

Prevention |

|---|---|---|

|

Fabric take-down rollers |

|

|

|

Belts of the fabric take-down |

|

|

|

|

|

|

Feed wheel rollers |

|

|

|

|

|

|

Yarn Guiding Parts

|

|

|

|

Yarn Carriers |

|

|

|

| |

|

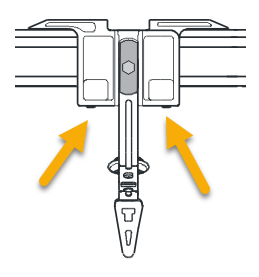

Autarkic yarn carriers (ADF) |

|

|

|

| |

|

Toothed belt of auxiliary take-down |

|

|

|

Toothed Belt

|

|

|

|

| |

|

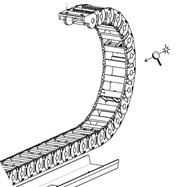

Energy chain trailing cable |

|

|

|

Battery |

|

|

|

|

|

|

|