Thoroughly cleaning needle bed

If the needle bed it not cleaned thoroughly and carefully, a non-uniform stitch appearance results during production due to needles that do not run smoothly, and the operation of the machine can no longer be ensured.

Thoroughly cleaning the needle bed:

- No fabric may be hanging on the needle bed.

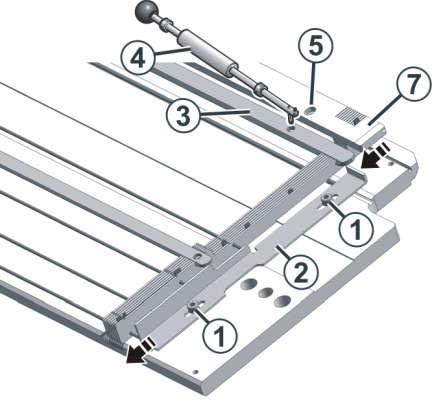

- 1

- Loosen both screws (1) and move the strip (2) downwards.

- 2

- Remove all needle rails (3) with the extraction hook (4).

- 3

- Remove all screws (5) of the jack bed.

- 4

- Take off jack bed (7).

- 5

- Remove needles, coupling part, intermediate slider and selector jacks.

မှတ်သား

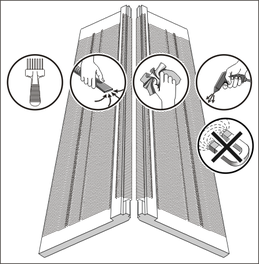

Dirt-caked needle channels due to oil or cleaning agent!

When the needle channels are cleaned with oil or cleaning agent, the dirt swells up and clogs the needle channels.

- Do not clean needle channels with oil or cleaning agent.

- Push dirt out of needle channels and blow out needle channels with compressed air.

- 1

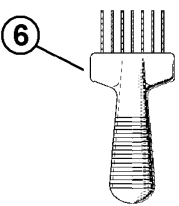

- Remove dirt out of needle channels, for example with a groove cleaner (6).

- 2

- Clean groove for pelerine spring of needle.

- 3

- Blow out dirt with compressed air from the needle bed.

- 4

- Check whether needles, coupling part, intermediate slider and selector jacks are undamaged.

- 5

- Clean needles, coupling part, intermediate slider and selection jacks with oil.

- 6

- Reassembly needle bed.

- 7

- Lubricate needles, coupling part, intermediate slider and selector jacks. If a central lubrication is installed, then use the setting for approx. 15 minutes.