Adjustment of the Intarsia Yarn Carriers with CMS Machines

I. Adjust the guidance of yarn carriers:

- 1

- To check whether the yarn carrier can be lifted from the yarn carrier rail, take the left and right sides of the yarn carrier housing in both hands and move the yarn carrier housing upward and downward.

- 2

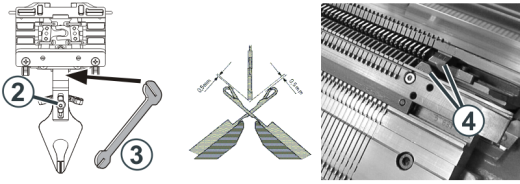

- If necessary push the setting key inwards with the adjusting key till the yarn carrier cannot be raised any more.

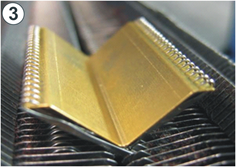

- 3

- Turn the setting key back by one-eighth of a turn.

Same procedure with normal and intarsia yarn carriers.

II. Adjustment of intarsia yarn carriers type 2:

The yarn carriers are correctly adjusted when:

- an unswiveled yarn carrier passes by a swiveled yarn carrier.

- the yarn carrier tips move exactly between the needle beds in the needle cross and the distance between yarn carrier tips and the closed needle latch is 0.5 mm to 1 mm

- The yarn carriers of the track 1 and 8 are also set 0.5 higher so that they do not touch the lateral limiters (4) of the needle bed.

Procedure for adjusting an intarsia yarn carrier type 2:

- 1

- Stop carriage assembly in needle area.

- 2

- Insert yarn carrier shims in needles:

|

|

|

|

|

|

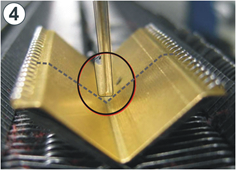

- 3

- Loosen the screw (2) to adjust the height of the yarn carrier.

- 4

- Adjust the height of the yarn carrier and re-tighten the screw (2).

- 5

- In order to adjust the position of the yarn carrier tip laterally, bend the yarn carrier bow carefully (without using force) by means of the adjusting part (3).

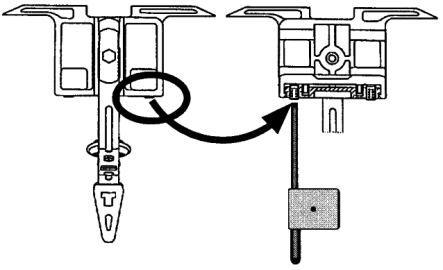

III. Move the intarsia yarn carrier in the area of the carriage:

Intarsia yarn carriers located in the area of the carriage cannot be shifted by hand. Use the shifting device.

- 1

- Press the lifters inward with the shifting device and shift the yarn carrier out of the area of the carriage.

IV. Check and correct the parking position of an intarsia yarn carrier:

As soon as an intarsia yarn carrier reaches the end of its working area, the yarn carrier plunger is lifted out of the yarn carrier. The yarn carrier is braked and swivels back into its color field.

|

Cause of wrong parking position |

Remedy |

|---|---|

|

Inner surface of the yarn carrier rail is oily or greasy |

Clean the oily or greasy braking surface of the yarn carrier rail. |

|

Stopping time of the yarn carrier is not set correctly |

Adjust the braking value of the yarn carriers directly on the machine. |

|

Pressure plates are worn |

Turn over or replace the pressure plates |