Remove the carriage part when the carriage assembly is blocked in the needle bed

In the case of a shock on the needle bed, the piezo-electric shock stop switches off the knitting machine.

|

Shock stop motion front needle bed | Shock stop motion rear needle bed |

|---|---|

|

|

Possible causes:

- Working butts of the movable parts (needle, coupling part, intermediate slider, and selection jack) are broken. This may have damaged trick walls as well.

I. Remove the carriage part from the needle bed

On tandem machines both carriage parts in the same needle bed are raised, even if only one carriage part is blocked.

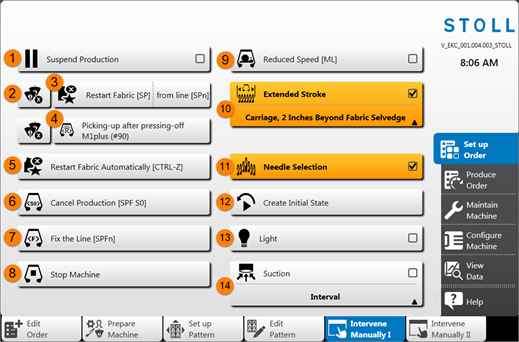

- 1

- Select the main area

Produce Order in the main navigation bar.

Produce Order in the main navigation bar.

You can open the  Intervene Manually I menu via

Intervene Manually I menu via  Set up Order of the main area as well.

Set up Order of the main area as well.

- 2

- Tap on in the bottom navigation bar:

Intervene

Manually I

Intervene

Manually I

1 |

|

| The production runs with active knitting program (default) | |

| The production is interrupted

| |||

2 |

| Deletion of the yarn carrier positions when loading a knitting program (EAY)

| ||

3 |

| Restart Fabric [SP] | from line [SPx]

| |

4 |

| Start Picking-up after pressing-off (#90) | ||

5 |

| Cancels the current fabric, and starts automatically a new one of the current position (knitting program) [Ctrl-Z] | ||

6 |

| Cancel production [SPF S0] and continue on an empty row | ||

7 |

| Fix the Line [SPFn] | ||

8 |

| Stop machine | ||

9 |

| Reduced Speed [ML] | ||

10 |

|

| The carriage only moves over the knitting area | |

| The carriage always moves over the entire needle bed | |||

11 |

| Switch needle selection on or off | ||

12 |

| Create Initial State | ||

13 |

| Switch light on and off | ||

14 |

| Switch on or off the vacuum device by selecting Permanent or Interval. | ||

- 3

- Deactivate the

of

of  Needle Selection.

Needle Selection. - The needle selection in the front and rear needle bed is switched off.

The key is white.

key is white. - 4

- Then, switch to

Monitor

Production in the bottom navigation bar.

Monitor

Production in the bottom navigation bar. - 5

- Open the Yarn Carriers window with the

Yarn Carriers button.

Yarn Carriers button. - Display of all yarn carriers: Plunger of active yarn carrier

at bottom

at bottom

- 6

- Tap on the

symbol of the active yarn carriers.

symbol of the active yarn carriers. - 7

- Tap a second time on the yarn carrier to pull up the plunger

- or -

Tap the button to switch off all yarn carrier plunger.

button to switch off all yarn carrier plunger.

- or -

Select Maintain Machine /

Maintain Machine /  Service in the main navigation bar.

Service in the main navigation bar. - 8

- Open the Service Functions for the Carriage window with the

Carriage button.

Carriage button. - 9

- Press the

key.

key. - All yarn carrier plungers are pulled up.

- 10

- Push all yarn carriers outward.

Central lubrication

If a central lubrication is present, swivel it into mounting position.

- 11

- Deactivate the

of

of  40 Volts.

40 Volts. - 12

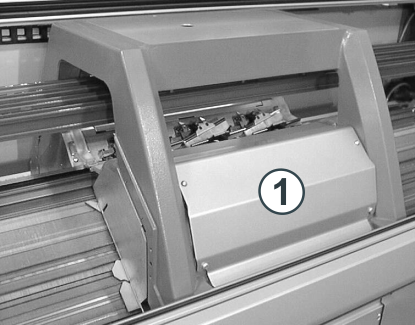

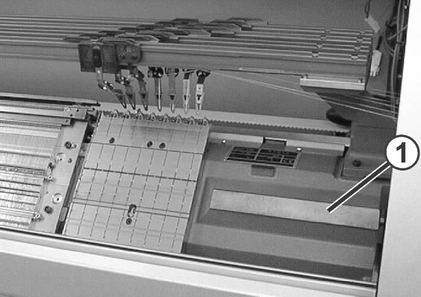

- Remove the carriage assembly panelling (1).

Pay attention to the needle detector when removing the rear carriage part.

- 13

- Remove the suction tube on the carriage assembly.

- 14

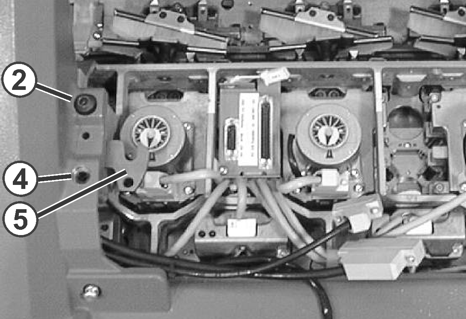

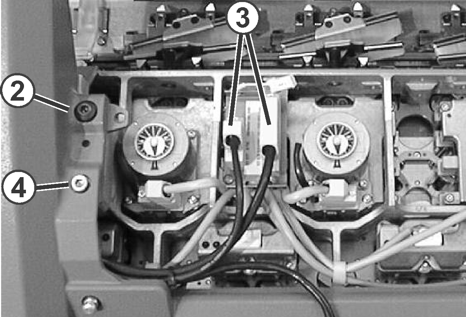

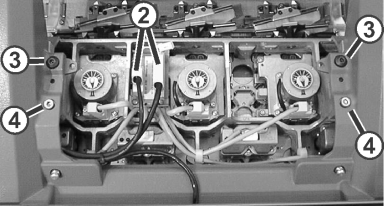

- Loosen the shoulder screws (2) and screws (4) on the left and right sides.

- 15

- Swivel left and right swiveling plates (5) inward.

- 16

- Set and tighten the screws (4) evenly, with it the carriage part is raised off the needle bed in the process.

- 17

- Loosen the screws on the plugs (3) and pull out the plugs.

- 18

- To lower the carriage part again, loosen the screws (4) on the left and right-hand sides.

- 19

- Remove the screws (4).

- 20

- Exit the Yarn Carrier Yarn Carriers window with the < Close button.

- 21

- Press the

Release Drive Brake [>!] button under

Release Drive Brake [>!] button under  Intervene

Manually II.

Intervene

Manually II.

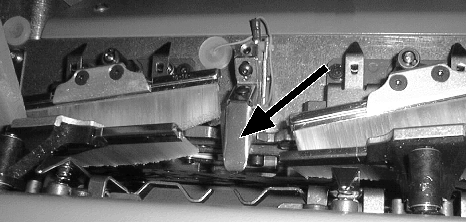

NOTICE

Damage to needles and knitting system!

There are still needles in the knitting system.

When moving the carriage assembly in the other direction (opposed to the carriage direction), the needles and knitting system can be damaged.

- Do not change the pushing direction of the carriage assembly!

- 22

- Push away the carriage assembly.

- 23

- Lift carriage part from needle bed.

- 24

- Check the carriage part and the needle bed.

If the carriage assembly is blocked:

The drive brake has automatically closed.

II. Check and clean the carriage part and the needle bed

Do not remove metallic parts and fragments (e.g. broken needle latch or needle hook) with a magnetic tool. There is a danger that the needle bed or cams can be magnetized, leading to incorrect selection.

-

Check the cams for damage.

Remove broken working butts of the movable parts (needle, coupling part, intermediate slider, and selection jack). -

Check the needle bed for damage.

Remove broken working butts of the movable parts (needle, coupling part, intermediate slider, and selection jack).

If trick walls are damaged, they have to be repaired.

- 1

- Clean the selection systems with a clean cloth.

- 2

- Clean the cams with a cloth and check them for wear and damage.

- 3

- Remove fragments if necessary

- 4

- Apply oil onto the cams with a brush.

For further information about cleaning the knitting and selection systems refer to the operating instructions.

III. Put the carriage part on:

- 1

- Mount the carriage part on the left or right outside the needle bed in such a way that it contacts the support surface (1).

- 2

- In the main navigation bar select the main area

Maintain Machine.

Maintain Machine. - 3

- Select

Service in the bottom navigation bar.

Service in the bottom navigation bar. - 4

- With the

Carriage button, open the Service Functions for the Carriage window.

Carriage button, open the Service Functions for the Carriage window. - 5

- With activate the setting

.

.

- The function is activated

and the button is now displayed in yellow.

and the button is now displayed in yellow.

- 6

- Press the

Release drive brake [>!] button.

Release drive brake [>!] button. - 7

- Push the carriage assembly right over the carriage part.

- 8

- Deactivate again the power supply

.

. - 9

- Uniformly screw in the shoulder screws (3) until the carriage assembly is raised somewhat.

- 10

- Swivel the left and right swiveling plates outward below the carriage assembly.

- 11

- Tighten the screws (3) and (4) uniformly.

- 12

- Insert the plug (2) and screw-in the safety screws on the plugs.

- 13

- Bring the yarn carriers into their basic positions.

- 14

- Mount the suction tubes on the carriage assembly.

- 15

- If necessary, bring the swiveled central lubrication again into working position.

- 16

- Assemble the carriage assembly panelling.

- 17

- Switch on 40 V power supply.

- 18

- Exit the window with

OK.

OK. - 19

- In the main navigation bar select the main area

Set up Order.

Set up Order. - 20

- Then, in the bottom navigation bar select

Intervene Manually I.

Intervene Manually I. - 21

- Press the

Cancel Production [SPF S0] button.

Cancel Production [SPF S0] button. - The knitting program is set to an empty row S0.

- 22

- Start the machine with the engaging rod.

- 23

- Move the left carriage to the reversal point.

- 24

- Switch needle selection on if necessary

- 25

- With the

Create Initial State button recover the initial state of the machine

Create Initial State button recover the initial state of the machine

- or -

Return to Edit Order to re-start the order.

Edit Order to re-start the order. - 26

- Tap the

Start Order key.

Start Order key.

: The machine runs with empty carriage stroke starting with the next reversal until the button is deactivated.

: The machine runs with empty carriage stroke starting with the next reversal until the button is deactivated.