Central lubrication

Starting with the 2023 change of component time, the ADF and CMS machines are equipped with a central lubrication as a standard equipment.

- If a central lubrication is mounted on the knitting machine you can switch it on and off.

- Central Lubrication - Differences of Type 1, Type 2 and Type 3

Central lubrication disabled

- The monitoring of the lubrication interval is automatically activated.

- The following lubrication tasks must be performed manually:

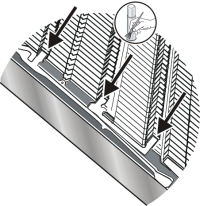

- Oil needle bed

- Oil jack bed

- Oiling carriage guide bar

|

Needle bed | |

|

|

Displays the quantity of the system run-throughs until the next oiling of the needle bed. |

|

|

Click this button only if the oiling process actually was performed.

|

|

|

Click this button only if the greasing process actually was performed.

|

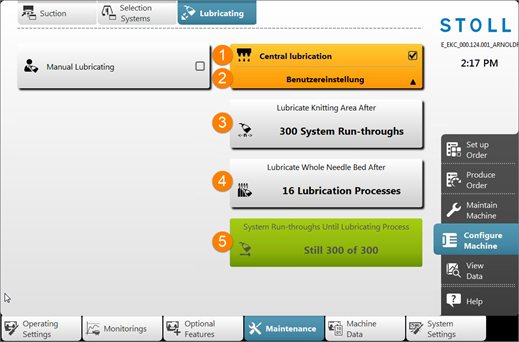

Activate the central lubrication:

With Restart and Configuration, you can select the central lubrication as option.

- You are signed in as Senior Operator

.

.

- 1

- Select

Configure Machine in the main navigation bar.

Configure Machine in the main navigation bar. - 2

- Tap on

Maintenance in the bottom navigation bar.

Maintenance in the bottom navigation bar. - 3

- Open the

Lubricating tab.

Lubricating tab.

- The following menu is displayed.

|

No. |

Function | ||

|---|---|---|---|

|

1 |

|

Central Lubrication | |

|

|

inactive | ||

|

|

Active | ||

|

2 |

Three settings are available for the lubrication interval: | ||

|

Initial Lubrication This setting is used for the initial lubrication of a new machine at the Stoll factory. Attention:

| |||

|

STOLL Specifications Use this setting for production. | |||

|

User Settings The user can change the values. Attention:

| |||

|

3 |

|

Input of the desired value (system run-throughs) for the lubrication interval forLubricate Knitting Area After | |

|

4 |

|

Input of the desired value (number of lubrication procedures) for the lubrication interval Lubricate Whole Needle Bed After | |

|

5 |

|

Number of system run-throughs since the last lubrication process. | |

- 4

- Activate the central lubrication with

Central Lubrication

Central Lubrication  button.

button. - 5

- Make further desired settings for the lubrication interval of the central lubrication.

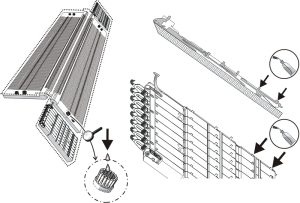

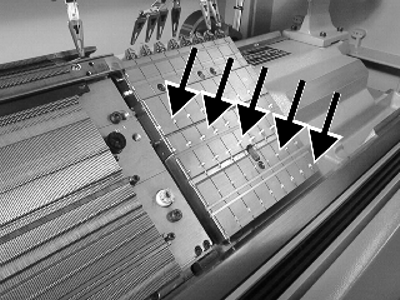

Oil the clamping and cutting device on the right

Only CMS 5xx / 5“ with central lubrication type 1 and 2

For mechanical reasons, the central lubrication does not reach all eight clamping positions.

- 1

- Use a brush to apply oil to all working butts of the clamping points.

System Run-throughs Until Lubricating Process

System Run-throughs Until Lubricating Process Confirm Oiling the Needle Bed

Confirm Oiling the Needle Bed