Thoroughly cleaning needle bed

|

|

Stolltex T46 |

E1,5.2│E2.2│E3│E3,5│E4│E5│E7│E8│E2,5.2│ |

|

Stolltex T32 |

E16│E18│E20│E8.2│E9.2│E10.2 |

The needle bed is cleaned daily by the operator. In addition, it must be cleaned thoroughly every 12 to 26 weeks.

If the needle bed it not cleaned thoroughly and carefully, a non-uniform stitch appearance results during production due to needles that do not run smoothly, and the operation of the machine can no longer be ensured.

Thoroughly cleaning the needle bed:

- No fabric may be hanging on the needle bed.

- The required tools (groove cleaner and extraction hook) are included with the accessories.

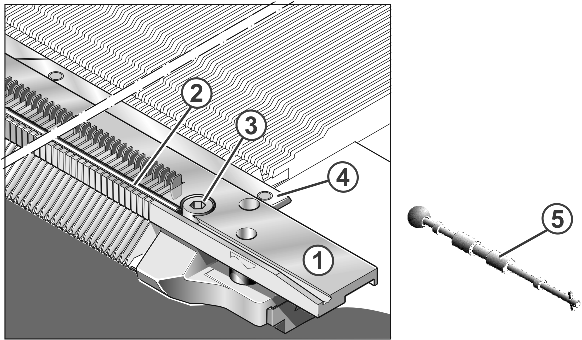

- 1

- Remove needle rail (4) with extraction hook (5).

With CMS 830 C, see CMS 830 C - Remove the needle rail - 2

- Remove screw (3) on left and right-hand sides of jack bed.

- 3

- Take off jack bed (1).

- 4

- Remove needles, coupling part, intermediate slider and selector jacks.

- 5

- In case of CMS 520 C and CMS 830 C take off the selection jack bed additionally.

Remove selection jack bed (CMS 520 C)

Remove selection jack bed (CMS 830 C)

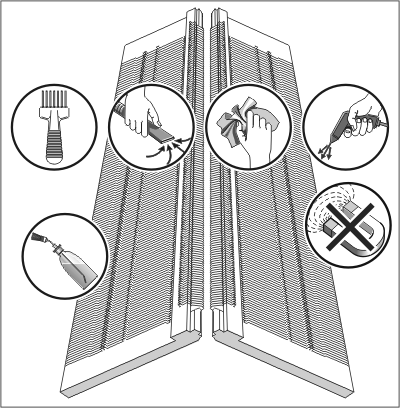

주목

Dirt-caked needle channels due to oil or cleaning agent!

When the needle channels are cleaned with oil or cleaning agent, the dirt swells up and clogs the needle channels.

- Do not clean needle channels with oil or cleaning agent.

- Push dirt out of needle channels and blow out needle channels with compressed air.

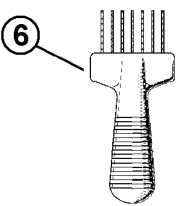

- 6

- Push dirt out of needle channels with groove cleaner (6).

- 7

- Clean groove for pelerine spring of needle.

- 8

- Blow out dirt with compressed air from the needle bed.

- 9

- Check whether needles, coupling part, intermediate slider and selector jacks are undamaged.

- 10

- Clean needles, coupling part, intermediate slider and selection jacks with oil.

- 11

- Pull out wire (2) to enable jack bed to be guided into holding-down jacks more easily during assembly.

- 12

- Reassembly needle bed.

- 13

- Lubricate needles, coupling part, intermediate slider and selector jacks.

If a central lubrication is installed, then use the setting for approx. 15 minutes.

Lubricating

The needle hooks and the holding-down jacks can be cleaned quickly and easily with the needle bed cleaning apparatus (special attachment).