Calculating correction values

The following examples are to show you how the ASCON device works.

Working with mm

Machine: CMS 530, gauge E12

Knitting mode: Single jersey (RL)

SEN =1-400

NP=12.0, this corresponds to a stitch length of 7.11 mm with E12 Stitch length (tables)

Calculation:

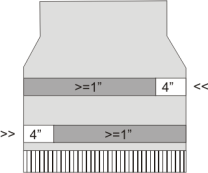

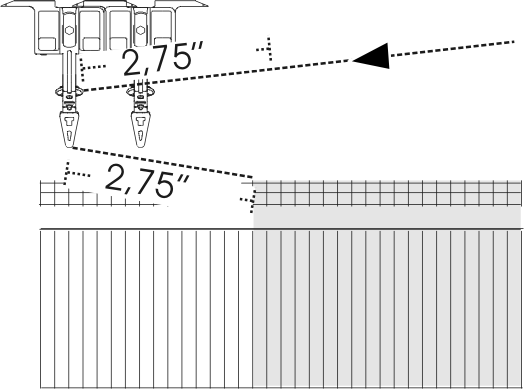

- 5 inches are deducted from the 400 needles (see drawing: ).

5 inches correspond to 60 needles with the gauge E12 (5 x 12 = 60). - 400-60 = 340 needles

- 340 x 7.11 mm = 2417.4 mm (target value for the yarn length)

At the beginning of the knitting row an area of 5 inches is not taken into account, as it would distort the measuring result (catch up and accelerate the yarn).

|

|

area not taken into account |

|

|

Measuring area |

The provided stitch length in each knitting row is detected by the ASCON device and passed onto the computer. The yarn length of several knitting rows will be summed up, separated by carriage direction. The sum is compared to the target value and a correction value is determined. If necessary, the computer adjusts the stitch cams so that more or less yarn is consumed.

If the knitting area of a row is smaller than 7 inches, no ASCON data is measured.

Parking position of the yarn carriers

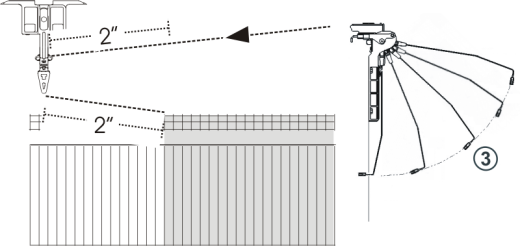

- The value for the yarn carrier distance may not be greater than . means: the yarn carrier is 2 inches away from the fabric selvedge (32 x 1/16 inch = 2 inches).

- 2 x 2 inches yarn length need to be caught up and accelerated (1 inch). If the YD value is greater than , this distance exceeds the area not taken into account of 5 inches. This distorts the measuring result.

Recommendation: - Reduce the restoring force of the yarn tensioner.

- minimize the yarn tensioning path of the yarn tensioner (position 3).

- If two yarn carriers are used on one rail, the ASCON device cannot optimally control due to the larger distance of the second yarn carrier. The second yarn carrier is at least 2.75 inches away from the fabric selvedge.

- 2 x 2,75 inches of yarn length need to be caught up and accelerated (1 inch). This distance lies outside the area not taken into account of 5 inches. This distorts the measuring result.

Working with original fabric

When , the target values are not calculated, but measured.

|

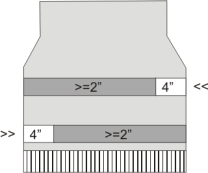

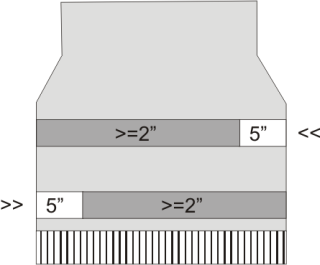

The minimum width is: | ||

|

5 inches for gauge E3 to E14 |

6 inches for gauges E16, E18, E8.2 and 9.2 | |

|

|

| |

|

|

area not taken into account | |

|

|

Measuring area | |

If the knitting area of a row is smaller than 5 inches (6 inches for E16, E18, E8.2, E9.2), no ASCON data is measured.

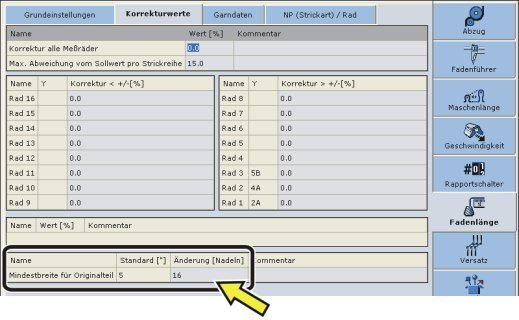

Changing the minimum width

If the error message is displayed, check the following items:

- If the yarn is threaded over the correct measuring wheel

- If the measuring wheel runs smoothly

- If the rubber running ring at the measuring wheel is OK

- If the yarn tension is OK (see previous section YLC1 - )

In case that the error message is still displayed, change the minimum width.

Changing the minimum width:

- In the Setup2 Editor call up the tab (Setup2 Editor -> Menu -> )

- In the column increase the value for the minimum width a little, for example by 16 needles.

Value range: - 2 E…0…+ 2 E (E = Number of needles per inch = Gauge of the machine)

Example for E16: - 32…0…+ 32 needles

- Confirm input

- Afterwards you need to knit the original fabric again.

- If the error appears again, enlarge the minimum width once more.